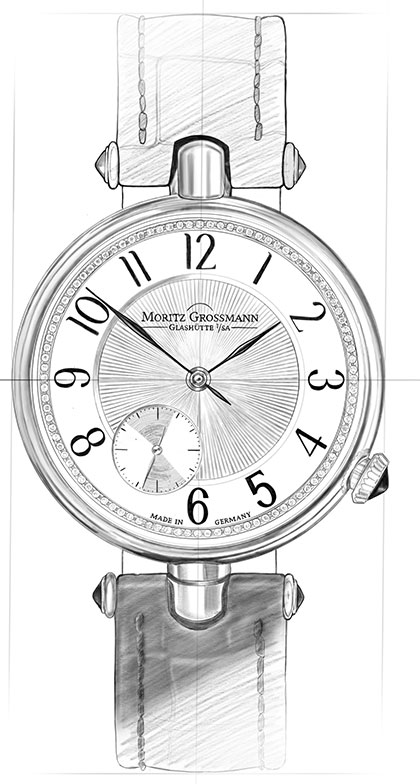

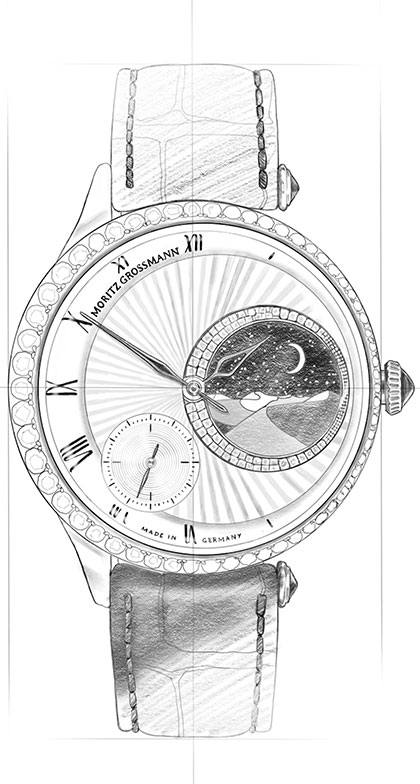

A watch made by Moritz Grossmann is the joint work of many talented hands: numerous techniques are practised at the manufactory in Glashütte, resulting in the creation of exceptional timepieces. The new TOURBILLON Tremblage now demonstrates the expressive power of traditional craftsmanship combined with modern aesthetics. The centrepieces are the painstakingly crafted dial with a tremblage surface created by hand and the sophisticated tourbillon mechanics. The new model comes in rose gold and white gold versions, each of which is limited to eight watches.

The new TOURBILLON Tremblage by Moritz Grossmann is founded on the visions and abilities of great craftspeople of the past and present. The watch brings the innovations of outstanding watchmakers of yesteryear and the present day together with the very best finishing and decorating techniques as maintained at the manufactory in Glashütte, the watchmaking town in Saxony.

TOURBILLON Tremblage in rose gold & white gold

The dial: staging the mechanics

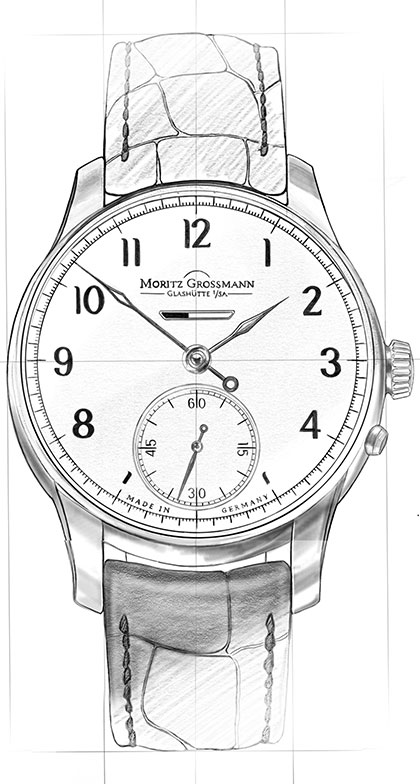

With absolute devotion, attention is paid both to the watch’s inner workings and its features. The TOURBILLON Tremblage’s dial is one of its special features – a multi-part construction made of German silver in a symmetrical design.

The inner part with tremblage revives a historical technique. It is engraved by hand using a variety of burins: the tools are moved across the metal in a trembling motion, which is also where the name comes from, with the French ‘tremblant’ meaning ‘to tremble’ in English.

The challenge is to achieve an even look, creating an effect which is both rough and matt. In the case of the inner dial of the TOURBILLON Tremblage model, this has been achieved to captivating perfection, as the tremblage surface softens the incident light, making it appear wonderfully matt. The other parts of the dial are matt opaline.

All the dial parts are subsequently galvanised in ‘black-or’ – an expressive anthracite colour. The processing of the dial, from the engraving to the finishing, requires several days to complete.

The presentation of time

At the heart of the dial visually is the tourbillon, which is flanked by the off-centre hour display at 3 o’clock and a second display at 9 o’clock. The hands are manually crafted from 750/000 gold in the rose gold version and from polished steel in the white gold version. The shapes of the handcrafted hands hint at their functions: the small second hand is more delicate, while the hour hand is stouter in design. They guarantee reliable time reading.

The fine tip of the minute hand sweeps past the minute scale around the dial’s outer perimeter. As the minute display is interrupted by the aperture for the tourbillon in the lower half of the dial, the minute hand has been extended beyond the centre. This counterpart now precisely presents minutes 25 to 35 on a scale. This twofold minute display is likewise a special Moritz Grossmann feature and is patented.

With its Arabic numerals in white and the very delicately tapered hands crafted at the company’s own manufactory, the TOURBILLON Tremblage showcases the clear aesthetics of the Glashütte precision measuring instruments of the 19th century.

The legacy of great watchmakers

The major personalities whose achievements serve as the basis for this latest innovation go by the names of Moritz Grossmann, Alfred Helwig and Abraham Louis Breguet. Grossmann, who founded the German School of Watchmaking in Glashütte in 1878, influenced watch manufacture in the 19th century and established a rich watchmaking legacy.

Carl Moritz Grossmann

Image: Archiv Deutsches Uhrenmuseum Glashütte

Carl Moritz Grossmann

Image: Archiv Deutsches Uhrenmuseum Glashütte

Alfred Helwig taught at the German School of Watchmaking in the first half of the 20th century and filed a patent application for the flying tourbillon in 1920. As the author of the book Drehganguhren on tourbillons, he inspires the design engineers at the Moritz Grossmann manufactory to this day.

Breguet was at work in Paris even earlier, in the 18th and the early 19th century. He influenced the watchmaking generations that followed with his developments. One of his best-known inventions is the tourbillon – a construction that mounts the escapement in a rotating cage to offset the effects of gravity on the balance. The tourbillon became a highly respected complication in wristwatches too as it attests to the very height of watchmaking expertise.

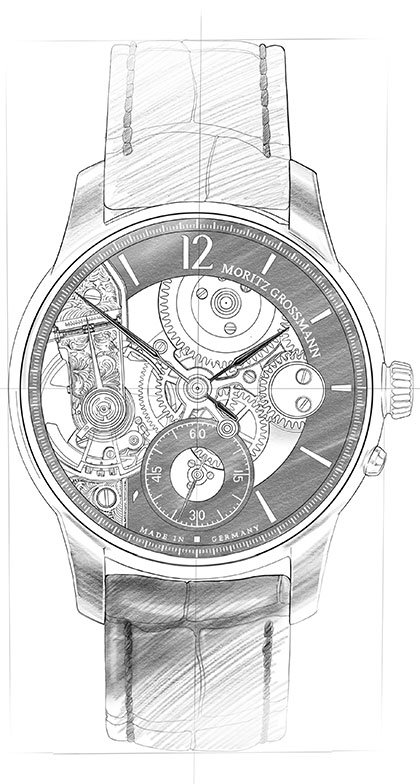

A modern version of traditional mechanics

The Moritz Grossmann manufactory unveiled the first calibre with a tourbillon more than ten years ago. It bears the company’s unmistakable signature as the manufactory does not settle for repeating the past, instead creating modern versions of traditional mechanics. This involves handed-down techniques being completely reimagined, such as the construction of the tourbillon in the hand-wound calibre 103.0.

What was created here was a generously sized oscillator which, influenced by Alfred Helwig, is only mounted on one side. The tourbillon is therefore visually impressive too, especially with its unusually large diameter of 16 millimetres and its reduced aesthetics.

It additionally boasts a longer cycle time: whereas traditional tourbillons generally turn on their axis once a minute, the Moritz Grossmann construction takes a full three minutes to perform a rotation. Other features include the filigree cage top resting on just two pillars and the characteristic V-shaped balance bridge, which is protected as a registered design.

Stop-second function with elastic brush made of hair

The cage’s elaborate design with two triangular pillars is the prerequisite for another special construction feature. According to the Grossmann watchmakers’ understanding, the precise mechanics of a tourbillon first call for exact time setting. To halt the balance uninterrupted, this stop device needs to avoid the frame pillars. An elastic brush made of human hair can easily glide past the triangular pillar and gently slow the balance down at the rim perimeter. The patented stop solution rounds out the mechanism in keeping with a Grossmann precision timepiece.

The finish: detailed perfection

The devotion with which timepieces are constructed and manufactured at Moritz Grossmann is also seen at the highest level at the decoration stage: each and every component is individually finished by hand. The plates and the tourbillon cock are finished with hand-engraved Glashütte ribbing, while edges which are bevelled by hand and three-band snailing on the ratchet wheel are especially aesthetic. The polished screws are set in gold chatons and the jewels are white sapphire.

Perfection in white gold and rose gold

The new TOURBILLON Tremblage is premiering in two versions: with a case in rose or in white gold and hands in rose gold or steel. The rose gold model is worn on a brown alligator leather strap, while the white gold version is combined with a black alligator leather strap. Both versions are limited to eight pieces each.

The TOURBILLON Tremblage in the Online Boutique

The new version of the TOURBILLON Tremblage and the entire collection are now available in the Moritz Grossmann Online Boutique.