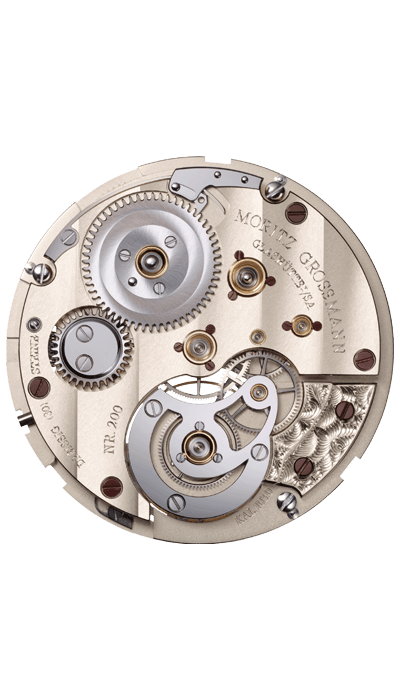

The movement

The calibre 103.0 movement of the BENU Tourbillon represents a new concept with a lineup of surprising solutions. The pillar movement with the main plate and the 2/3 plate, a typical hallmark of Grossmann watches, embodies the traditions of Glashütte pocket chronometers. A balanced ensemble of components in untreated German silver with different types of finissage and two pillar spacers constitute the tiered calibre that features a separately removable winder module. The delicate engravings are all fashioned by hand.

The Grossmann Three-Minute-Tourbillon with stopp second

The BENU Tourbillon reflects the talent of famous Glashütte watchmaker Alfred Helwig who developed the flying tourbillon in 1920. From 1911 onward, Helwig crafted watches in his own workshop and taught classes at the German School of Watchmaking in Glashütte after having been enrolled there himself as a student. His reference book entitled “Drehganguhren” also provided guidance in 2013 when the Grossmann three-minute tourbillon was developed.

In the BENU Tourbillon, the cage is suspended from a cantilevered, hand-engraved German-silver cock. Its design is totally new, resulting in minimal-art aesthetic appeal. The elaborately crafted upper part of the cage is a striking V-shaped balance bridge for which a design patent has been registered. Its hairspring is located beneath the characteristic Grossmann balance wheel. Thus, the aficionado’s glance is instantly directed to the heart of the BENU Tourbillon.

The tourbillon cage

Optimised for artisanal manufacturing techniques, the new design of the Grossmann balance improves the adjustability of inertia and achieves high kinetic energy combined with minimised air resistance and the smallest possible mass. With poising weights and equidistant bores in the balance-wheel rim, the mass can be varied and the balance trued. In the BENU Tourbillon, the size of the balance and of the cage was optimised with a creative spatial arrangement. The Nivarox 1 balance spring, with a terminal overcoil as calculated by Glashütte regleur Gustav Gerstenberger, is located beneath the balance so that the motion of the balance and tourbillon cage can be observed without obstruction.

The stopp second

As understood by Grossmann’s watchmakers, the precision of a tourbillon calls for a stop-seconds mechanism. The lavish execution of the cage with only two triangular posts paves the way for this extra complication. For trouble-free immobilisation of the balance, any kind of interference between the stop device and the triangular frame posts must be prevented. An elastic brush with human hair solves this problem gently and reliably. This patent-pending stop solution allows precise handsetting and delivers proof of the superiority of the BENU Tourbillon (the patent application is endorsed by SIGNO, an initiative of the German Federal Ministry of Economics and Technology).

The escapement

The pallet lever is composed of two parts: a thin fork with a blade-type guard pin, fashioned in the manner of Glashütte pocket watches, and the lever body with the visible sapphire pallets. The deflection of the lever is limited by a pin at the extension of the fork, which significantly improves the lever’s mass distribution and equilibrium.

The main spring barrel bearing

A very rarely used, optimised bearing system was chosen for the barrel. The bilateral jewel bearing with a maximised distance between the ratchet wheel and the main plate provides perfect stabilisation for the mainspring barrel. The modified Glashütte stopwork holds the tension of the mainspring. Because it slides in a slotted hole, the stop click allows the ratchet wheel to recoil somewhat after winding, which slightly relaxes the mainspring.

A gold chaton with a jewel adorns the ratchet wheel, a distinctive feature of the bilateral barrel bearing system.

The twin jewel bearings of the mainspring barrel arbor can be seen in the cross-section view.

The wheel train

Grossmann’s latest-generation precision timepieces stand for ORIGIN OF A NEW TIME beyond our era. It was also a key objective to preserve the beauty of the wheel train of the BENU Tourbillon, with its precious decorations and polishes, by precluding oxidation and damage to coated surfaces. Long-term brilliance of the train wheels is assured by ARCAP, a copper-nickel-zinc alloy. The balance, crafted from beryllium bronze, has a stately presence above the silvery shimmer of the going train.

The pinion break made of guaiacum

An additional wheel extends the periodicity of the cage to three minutes, thus reducing overall kinetic energy and the exposure of the escapement to stress. The pinion for the seconds is segregated from the power flow of the wheel train and driven with reduced torque. To prevent arbor and seconds-hand backlash, the pinion is constantly braked by a spring. Grossmann’s watchmakers designed this function in a sustainable and maintenance-free manner by choosing guaiacum, a very oily wood with the highest degree of hardness (“rock-hard”), for the brake ring of the fourth-wheel arbor. This solution was inspired by the extremely dependable marine and tower clocks that carpenter John Harrison crafted in the 18th century thanks to his insights into the properties of different wood species.

The three band snailing

The winding wheels have polished bevel faces in the toothing and sparkle with exceptional brilliance. The largest one, the ratchet wheel, is also decorated with traditional three-band snailing, accentuating a harmonious match with the wide ribbing and the freehand engravings.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

The engravings by hand

All engravings and inscriptons on the 2/3 plate and the tourbillon cock are always engraved by hand.

Tech Specs

Movement

Manufacture calibre 103.0, manually wound, adjusted in five positions

Functions / features

Flying three-minute tourbillon with screw-secured driving wheel and V-shaped balance bridge (design patent pending) / Sweep minutes, off-centre hours and seconds with stop seconds, replacement of the missing minute scale segment from 25 to 35 minutes with a separate scale swept by the extension of the minute hand on the opposite side (patent pending) / Stop seconds at the balance wheel rim with a pivoting fine-hair brush (patent pending) / Asymmetric-arm lever escapement with counterweight and lever banking pin / Grossmann balance with suspended balance spring, adjustable with poising screws in the rim / Newly developed mainspring barrel jewel bearing / Brake ring on the fourth-wheel arbor made of very hard, oily guaiacum / ARCAP train wheels / Grossmann winder with pusher to deactivate the handsetting mode and start the movement / Modified Glashütte stopwork with backlash / Pillar movement with 2/3 plate and frame pillars in untreated German silver / Hand-engraved 2/3 plate and tourbillon cock / Broad horizontal Glashütte ribbing / 3-band snailing on the ratchet wheel / Raised gold chatons with pan-head screws / White sapphire bearing jewels / Separately removable clutch winder

No. of parts

245 (wheel train 186, cage 59)

No. of jewels

30, 4 of which in screwed gold chatons (wheel train 17, cage 13)

Escapement

Lever escapement

Oscillator

Grossmann three-minute tourbillon with stop seconds; shock-absorbed Grossmann balance with 4 inertia and 2 poising screws, suspended Nivarox 1 balance spring with No. 80 terminal curve, Gerstenberger geometry

Cage diameter

16.0 mm

Cage speed

1 revolution in three minutes, anti-clockwise when viewed from dial side

Balance diameter

14.2 mm, frequency 18,000 semi-oscillations per hour

Power reserve

72 hours when fully wound

Operating elements

Crown to wind the watch and set the time, pusher to start the movement

Movement dimensions

Diameter: 38.4 mm, height: 7.1 mm