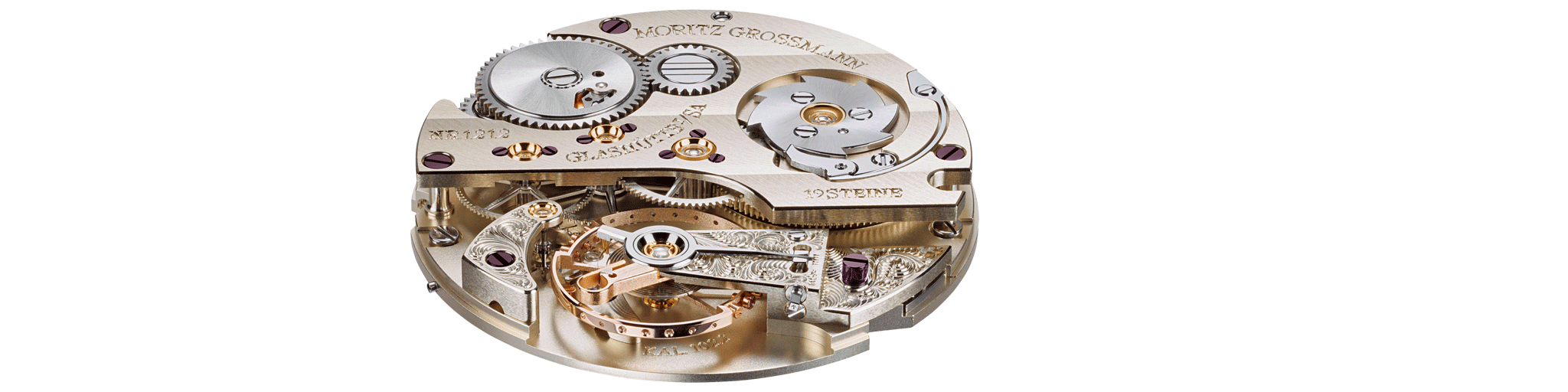

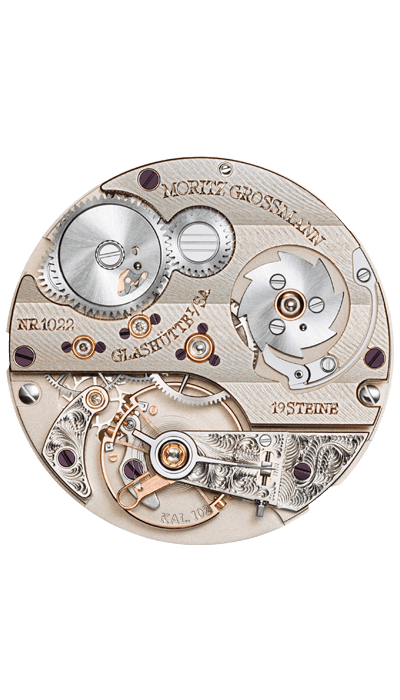

The movement

The calibre 102.2 is essentially an offshoot of the calibre 102.1 and also has a diameter of 26 mm. To create a comfortable winding mechanism especially for smaller watches, a rotatable strap attachment was integrated in the case at 6 o‘clock. It transfers turns of the strap into the movement via a toothed stem. The strap is very easy to grasp and rotate. Thus, the strap winder fully winds the watch with merely a few bidirectional twist motions.

The movement is again designed as a pillar calibre. A separately removable winder module incorporates all of the strap winder functions. Since the movement is exposed to torque while being wound, it is stabilised in the case with a lateral pin. The escape wheel and the pallet lever are mounted on a separate cock which simplifies the removal of the individual escapement parts. The size of the escape wheel cock was minimised to keep the view of the escapement as uncluttered as possible.

The strap winder with setting crown

The power needed to tension the mainspring is built up with a winding stem that enters the case at 6 o‘clock. To assure that the strap comfortably hugs the wrist, both the winding stem and the strap bar on the opposite side are inclined inward by 22°. A special bevel gear pair establishes the connection between the inclined winding stem and the horizontally orientated movement. When the watch is being wound, the strap can deliver much more torque than a crown because it is easy to grasp. The energy is swiftly transmitted via a bevel gear to two wheel sets with a high-efficiency ratio. A backstop ratchet allows bidirectional winding. Only very few back-and-forth motions of the strap are needed to fully wind the watch. Inside the case, the movement was turned by 30°, so the timesetting crown is positioned at 4 o‘clock. As before, the handsetting mechanism is activated by pulling the setting crown.

The stopwork

Since the winding stem could turn with the strap while the watch is being worn, the backstop tolerates a certain amount of deflection without causing the stop click to instantly block the stem. The backstop and the main stopwork are dimensioned such that the engagement of a pawl requires a rotation of at least 20°.

The ratchet wheel has only eight teeth, so the stopwork cannot be overloaded when very fast winding movements are performed. In the calibre 102.2, a mainspring with a bridle — commonplace in selfwinding watches — prevents damage that could be caused by excessive force. The bridle is pressed against the inside of the mainspring barrel and generates frictional torque that as a rule is 10% higher than the maximum torque of the spring. So when the mainspring is fully wound, turning the crown is met with resistance but it does not lurch.

The oscillator with stop seconds

The Grossmann balance, modified for the TEFNUT calibres, is clearly smaller than in the larger ATUM and BENU movements. It is designed for a high moment of inertia with minimal mass and beyond the mass and poising screws offers sufficient precision adjustment options.

The stop-seconds mechanism is activated when the setting crown is pulled. A spring firmly attached to the main plate presses against the safety roller and thus prevents inadvertent contact with the polished outer surface of the balance-wheel rim or maladjustment of the delicate poising screws. The spring is controlled by a linkage-type slide that for the strap winder is connected directly with the arresting spring and is thus uncoupled from the winding motion.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

The engravings by hand

All engravings and inscriptons on the 2/3 plate and the balance cock are always engraved by hand.

Tech Specs

Movement

Manufacture calibre 102.2, manually wound, adjusted in five positions

Special features

Shock-resistant balance with inertia and poising screws, impulse pin integrated in rim / flat balance spring / balance staff with integrated safety roller / index adjuster with Grossmann micrometer screw / plate movement with 3/5 plate, frame pillars, and separately removable clutch winding mechanism / frame parts in untreated German silver / raised gold chatons with pan-head screws / remodified Glashütte stopwork with backlash / mainspring barrel with bilateral jewel bearings for optimised power management / ARCAP train wheels / proprietary escapement with 18-tooth escape wheel

Functions

Hours and minutes

No. of parts

200

No. of jewels

19 jewels, 3 of which in screwed gold chatons

Escapement

Lever escapement

Oscillator

Shock-resistant Grossmann balance with 4 inertia and 2 poising screws, Nivarox 1 balance spring

Balance

Diameter 10.0 mm, frequency 21.600 semi-oscillations per hour

Power reserve

48 hours when fully wound

Movement dimensions

Diameter: 26.0 mm, height: 4.2 mm