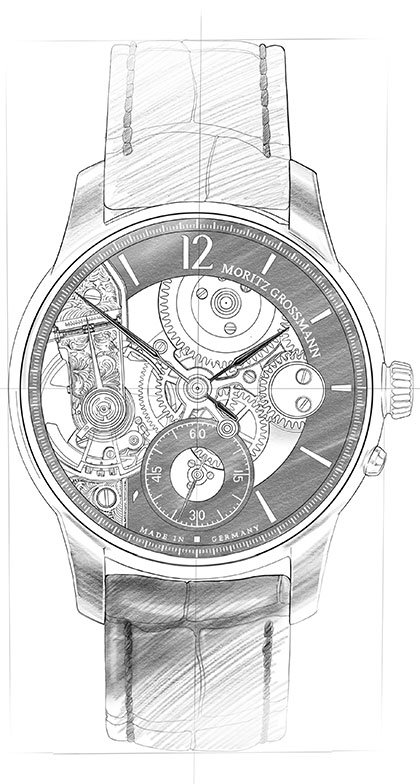

The movement

With a diameter of 26 mm and a height of just 4 mm, the calibre 102.1 movement echoes the slender elegance of the calibre 102.0. However, the systematically classic base design with a 2/3 plate reflects a greater affinity with the 100-series movements. The typical Grossmann elements with the High-Artistic Finish are embodied in the calibre 102.1 as well.

With a totally redesigned escapement, modified adjustment concept, and classic wheel train arrangement, the calibre 102.1 presents itself as a balanced and compact movement that gives Grossmann‘s engineers ample latitude for further developments in pure watchmaking artistry.

The escapement

The newly developed, asymmetricarm escapement has a smaller lever swing angle and a longer fork, which streamlines unlocking and improves the impulse behaviour.

Moritz Grossmann was already aware of the unwanted sticking effect of lubricants and countered it by minimising the contact surface between the escape wheel and the pallets. He did this by using pointed-tooth escape wheels that were commonplace in England, but we achieve the effect with a club-tooth escapement and particularly slender pallets. This significantly reduces the difference between the two impulses. The galvanoplastic production of the escape wheel allows small steps of merely 0.03 mm depth at the bottom sides of the teeth, so the capillary effect retains the oil better.

The index adjuster

The adjustment function allows the oscillator to be tweaked very conveniently without necessitating its removal. The micrometer screw is easily accessible when the caseback is removed.

The cantilevered balance cock features a rotatable stud holder that is normally secured with the clamping screw which is visible on top of the cock. Thus, the micrometer screw can be used to sensitively calibrate the pointer and to accurately adjust the watch. As soon as the clamping screw is loosened, the pointer and the stud holder can be jointly turned to allow the beat to be set with the precise Grossmann micrometer screw without affecting the rate.

The wheel train

In this movement as well, the mainspring barrel is suspended between bearings on both sides. With the screwed ratchet wheel, the hollow barrel core is integrated in the train bridge and can thus accommodate the upper jewel bearing of the mainspring barrel. Here, too, its chaton assures that the ratchet wheel is centred. The going train features a classic centre wheel and a seconds subdial at 6 o‘clock.

The train wheels are made of ARCAP, a copper-nickel-zinc alloy finished with polished chamfers and circular graining to assure long-lasting beauty and brilliance.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

The engravings by hand

All engravings and inscriptons on the 2/3 plate and the balance cock are always engraved by hand.

Tech Specs

Movement

Manufacture calibre 100.2, manually wound, adjusted in five positions

Special features

Shock-resistant balance with inertia and poising screws, impulse pin integrated in rim / flat balance spring / balance staff with integrated safety roller / index adjuster with Grossmann micrometer screw / plate movement with 3/5 plate, frame pillars, and separately removable clutch winding mechanism / frame parts in untreated German silver / raised gold chatons with pan-head screws / remodified Glashütte stopwork with backlash / mainspring barrel with bilateral jewel bearings for optimised power management / ARCAP train wheels / proprietary escapement with 18-tooth escape wheel

Functions

Hours and minutes

No. of parts

188

No. of jewels

22 jewels, 3 of which in screwed gold chatons

Escapement

Lever escapement

Oscillator

Shock-absorbed Grossmann balance with 4 inertia and 2 poising screws, Nivarox 1 balance spring with No. 80 Breguet terminal curve, Gerstenberger geometry

Balance

Diameter 10.0 mm, frequency 21.600 semi-oscillations per hour

Power reserve

48 hours when fully wound

Movement dimensions

Diameter: 26.0 mm, height: 3.45 mm