The movement

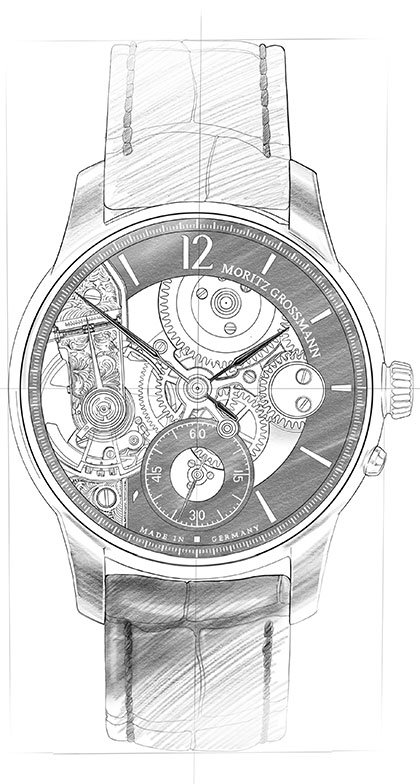

The calibre 100.3 with the jumping date is based on the calibre 100.1. It is also a pillar movement with a 2/3 plate. All of its elements are crafted in the manufacture, including train wheels, stopwork, escapement, and oscillator, and then endowed with the High-Artistic Finish to spotlight their characteristic beauty. The additional jumping date mechanism is composed of parts of varying complexity that are integrated in the movement on the dial side.

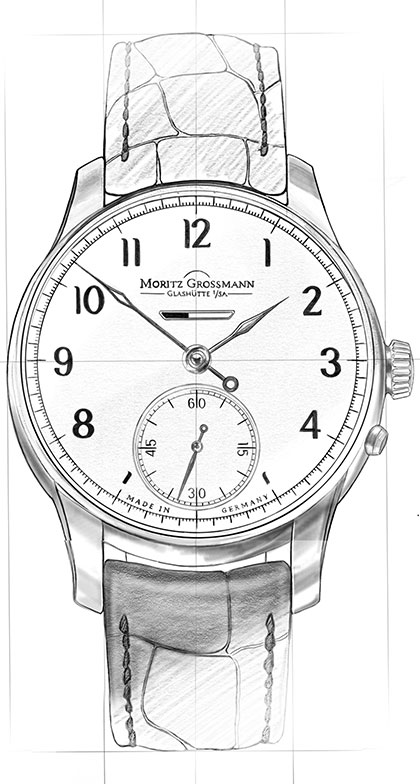

Grossmann‘s watchmakers explored new avenues to develop a delightful solution for the date display complication. The jumping date stands out with convenience and precise functionality. With a complete scale and the moving marker on the periphery, the date display of the ATUM Date emphasises the perfection of pure watchmaking artistry in this application for the first time.

The jumping date display

The jumping date display of the calibre 100.3 relies on a complex system composed of a date switching wheel, a release lever, a switching star and a date ring with the marker.

The date switching wheel consists of the wheel itself, a ring-shaped switching finger spring, and the switching finger. The switching finger can freely rotate on the wheel but is secured by the ring spring in a position that allows movements on both sides but always requires tensioning of the spring. The mechanism is powered by the hour wheel at a ratio of 2:1, so the switching wheel rotates anticlockwise once every 24 hours. The transmission ratio of the date marker mechanism is calculated to 11.6°, so the increments of the date marker ring add up to a total of 31 days.

The datesetting mechanism

Apart from the precisely jumping date, this type of date display has the advantage that the switching finger does not engage with the date switching wheel except for the few milliseconds during which the jump to the next date is taking place. Thus, the date can be corrected in either direction at any time.

The separate setting crown at 10 o‘clock allows the date to be corrected, for instance at the end of a month. Normally, this setting crown is not active, so inadvertent corrections are prevented. The crown must be pulled out to set the date. During the process, the movement continues to run and the date can be set by turning the crown in either direction. A jumper spring causes the date ring with the marker to precisely engage in the right position.

The date ring with marker

The ATUM Date is the first watch to be endowed with the calibre 100.3. A complete clockwise date scale from 1 to 31 is located on the outer periphery of the dial. The blue date numerals clearly contrast against the applied hour markers. To avoid competition between the date indicator and the hour and minute hands, it points to the date from the outer circumference instead of from the centre. It is positioned on a date ring beneath the dial. The ring, with the marker, moves along the scale in steps of one day. The prominent bracket-style date marker is manually crafted and annealed to a brown-violet hue. It frames the current date numeral, assuring superb legibility.

The Grossmann balance

The BENU Power Reserve breathes at a calming traditional rate of 18,000 semi-oscillations per hour. The calibre 100.2 premieres the newly designed Grossmann balance and demonstrates that rate accuracy is not achieved solely with a higher frequency. Optimised for artisanal manufacturing techniques, the design of the balance improves the adjustability of inertia and achieves high kinetic energy combined with minimised air resistance and the smallest possible mass. The number of screws in the balance-wheel rim was minimised as well. Mass screws with different head lengths are used to incrementally vary the moment of inertia. Additionally, the rim is provided with uniformly spaced bores that allow reductions in mass or contribute to the poising of the balance. The smooth cylindrical balance staff is integrated in the hub and can easily be replaced if necessary. The Grossmann balance interacts with a Nivarox balance spring which is overcoiled with a quarter arc on the inside and secured to the slotted roller with a brass pin.

The Grossmann winder with pusher

On average, a manually wound watch is reset weekly. It was a challenge for the watchmakers at Grossmann to improve the functional reliability and convenience of this operation. When the user briefly pulls the winding crown out, this mechanism switches to the handsetting mode and stops the movement. The crown immediately returns to its home position but can be turned to precisely set the hands. Afterwards, the movement is restarted with the pusher adjacent to the winding crown without altering the positions of the hands. At the same time, the mechanism switches back to the winding mode. This ingenious handsetting mechanism eliminates two possible error sources: the ingress of particles into the case while the hands are being set and the unintentional alteration of the hand positions while the crown is being pushed home again.

The index adjuster

The BENU Power Reserve features an index adjuster that allows the watch to be regulated very precisely without disturbing the equilibrium of the oscillation system. The Grossmann micrometer screw enables accurate, tension-free adjustments of the index tail in both directions.

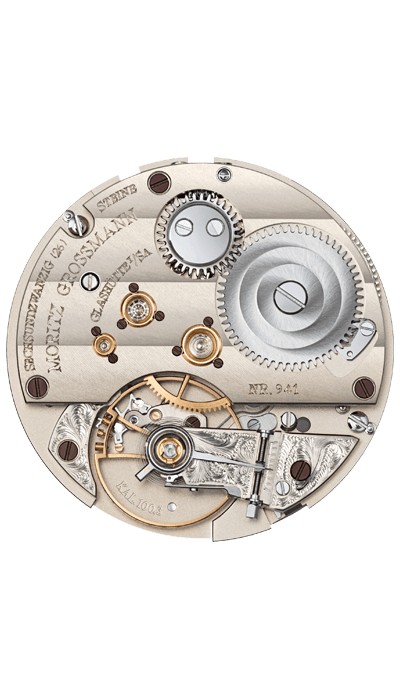

The three-band snailing

The winding wheels have polished bevel faces in the toothing and sparkle with exceptional brilliance. The largest one, the ratchet wheel, is also decorated with traditional three-band snailing, accentuating a harmonious match with the wide ribbing and the freehand engravings.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

The engravings by hand

All engravings and inscriptons on the 2/3 plate and the balance cock are always engraved by hand.

Tech Specs

Movement

Manufacture calibre 100.2, manually wound, adjusted in five positions

Special features

Grossmann balance; hand setting override and start of movement with lateral pusher; precisely jumping date display with a peripheral marker; bidirectional date adjustment with a separate crown at 10 o'clock; space-saving modified Glashütte stopwork with backlash; adjustment with Grossmann micrometer screw on cantilevered balance cock; pillar movement with 2/3 plate and pillars made of untreated German silver; balance cock and escape-wheel cock hand-engraved; broad horizontal Glashütte ribbing; 3-band snailing on the ratchet wheel; raised gold chatons with pan-head screws; separately removable clutch winding mechanism; stop seconds for hand setting

Functions

Hours and minutes, subsidiary seconds with stop seconds, Grossmann manual winder with pusher

No. of parts

259

No. of jewels

26 jewels, 3 of which in screwed gold chatons

Escapement

Lever escapement

Oscillator

Shock-absorbed Grossmann balance with 4 inertia and 2 poising screws, Nivarox 1 balance spring with No. 80 Breguet terminal curve, Gerstenberger geometry

Balance

Diameter 14.2 mm, frequency 18,000 semi-oscillations per hour

Power reserve

42 hours when fully wound

Movement dimensions

Diameter: 36.4 mm, height: 7,56 mm