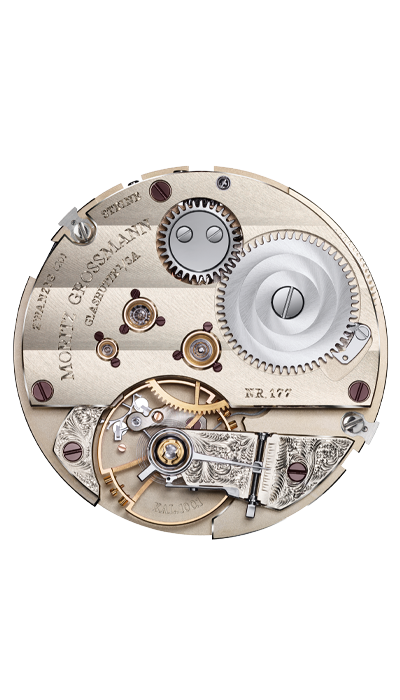

The movement

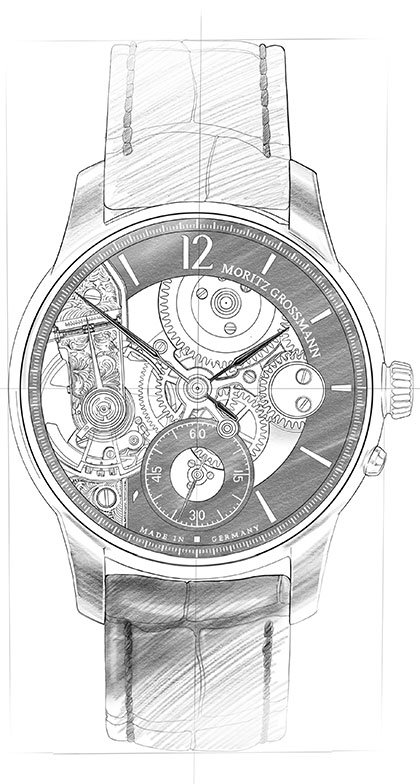

Through an ample, non-reflective sapphire-crystal display back, the calibre 100.1 movement reveals itself to aficionados of fine timekeeping instruments as a fusion of the arts. Subtly proportioned components in untreated German silver with different types of finissage constitute the individual levels. As was the case in Glashütte pocket chronometers, the movement consists of a main plate and a 2/3 plate precisely spaced apart with two posts and the barrel bridge. Raised gold chatons and pan-head chaton screws add three-dimensional accents. The brilliant glitter of hand-polished chamfers on going-train wheels and the edges of levers and springs resides in the depths of the movement as well.

Several innovations in the calibre 100.1 movement are noteworthy in the ways they further optimise the handling convenience and functional reliability. The newly designed Grossmann balance can now be crafted in-house in its entirety. A further modification of the Glashütte stopwork created space for the Grossmann winder with pusher.

The Grossmann balance

The ATUM breathes at a calming traditional rate of 18,000 semi-oscillations per hour. The calibre 100.1 incorporates the newly designed Grossmann balance and demonstrates that rate accuracy is not achieved solely with a higher frequency. Optimised for artisanal manufacturing techniques, the design of the balance improves the adjustability of inertia and achieves high kinetic energy combined with minimised air resistance and the smallest possible mass. The number of screws in the balance-wheel rim was minimised as well. Mass screws with different head lengths are used to incrementally vary the moment of inertia. Additionally, the rim is provided with uniformly spaced bores that allow reductions in mass or contribute to the poising of the balance. The smooth cylindrical balance staff is integrated in the hub and can easily be replaced if necessary. The Grossmann balance interacts with a Nivarox balance spring which is overcoiled with a quarter arc on the inside and secured to the slotted roller with a brass pin.

The Grossmann winder with pusher

On average, a manually wound watch is reset weekly. It was a challenge for the watchmakers at Grossmann to improve the functional reliability and convenience of this operation. When the user briefly pulls the winding crown out, this mechanism switches to the handsetting mode and stops the movement. The crown immediately returns to its home position but can be turned to precisely set the hands. Afterwards, the movement is restarted with the pusher adjacent to the winding crown without altering the positions of the hands. At the same time, the mechanism switches back to the winding mode. This ingenious handsetting mechanism eliminates two possible error sources: the ingress of particles into the case while the hands are being set and the unintentional alteration of the hand positions while the crown is being pushed home again.

The three-band snailing

The winding wheels have polished bevel faces in the toothing and sparkle with exceptional brilliance. The largest one, the ratchet wheel, is also decorated with traditional three-band snailing, accentuating a harmonious match with the wide ribbing and the freehand engravings.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

The engravings by hand

All engravings and inscriptons on the 2/3 plate and the balance cock are always engraved by hand.

Tech Specs

Movement

Manufacture calibre 100.1, manually wound, adjusted in five positions

Special features

Grossmann balance; lateral pusher for disabling the handsetting mode and starting the movement; space saving and modified Glashütte stopwork with backlash; adjustment with Grossmann micrometer screw on a cantilevered balance cock; Pillar movement with 2/3 plate and frame pillars in untreated German silver; 2/3 plate, balance cock, and escape-wheel cock engraved by hand; broad horizontal Glashütte ribbing; 3-band snailing on the ratchet wheel; raised gold chatons with pan-head screws; separately removable clutch winder; stop seconds for handsetting

Functions

Hours and minutes, subsidiary seconds with stop seconds, Grossmann winder with pusher

No. of parts

198

No. of jewels

20 jewels, 3 of which in screwed gold chatons

Escapement

Lever escapement

Oscillator

Shock-absorbed Grossmann balance with 4 inertia and 2 poising screws, Nivarox 1 balance spring with No. 80 Breguet terminal curve, Gerstenberger geometry

Balance

Diameter 14.2 mm, frequency 18,000 semi-oscillations per hour

Power reserve

42 hours when fully wound

Operating elements

Crown for winding the watch and setting the time, pusher to start movement

Movement dimensions

Diameter: 36.4 mm, height: 5.0 mm