The movement

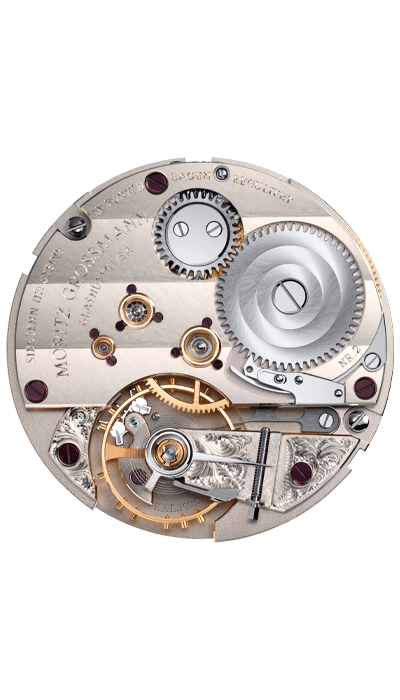

The construction of the calibre 100.0 movement that the Benu reveals within the transparent back not only addresses all of its functional aspects, but is also a feast for the eyes of any watch connoisseur. The 2/3 plate made of German silver — a hallmark of Glashütte pocket chronometers — replaces a number of bridges for enhanced stability. The Grossmann plate has two typical features: the straight-cut edges and the generous circular segment cutout that showcases the classic screw balance in its entirety.

The balance and the winding wheels are in visual equilibrium. The space between them is adorned with three screwed gold chatons that hold sparkling white sapphire jewels. As the visible screws are annealed, they glisten with a lustrous brown-violet hue.

The naked eye perceives the mechanical movement as a functional work of art. Polishes, graining, snailing, and wide Glashütte ribbing embellish the parts, and the inscriptions are always engraved by hand. German silver, steel, the annealing tint of the screws, together with the gold of the chatons and of the large balance wheel rim constitute a classically discreet composition of natural material colours. A jeweller’s loupe allows the observer to delight in the superb finishing of the surfaces and the bevelled, mirror-polished edges, whilst on a visual excursion across the individual levels of the movement.

The escapement

A classic lever escapement establishes the link between the going train and the oscillation system of the calibre. Found in almost all mechanical watches, this escapement was modified according to considerations proposed by Hugo Müller (1863 to 1943), a well-known Glashütte regleur. The banking pins were shifted away from the pallet fork closer to the pallet arms, so their limiting action takes place where the mass is larger.

The oscillation system

The classic screw balance breathes with a Nivarox hairspring featuring a terminal curve that was first calculated by regleur and chronometer maker Gustav Gerstenberger (1886 to 1983) in Glashütte. It performs 18,000 semi-oscillations per hour, which is equivalent to the traditional frequency of 2.5 hertz. On the inside, the balance spring is overcoiled with a quarter arc and pinned to the roller. The system does not have the adjustable stud that is commonplace today. It was eliminated in favour of a firmly secured balance spring stud.

The oscillation system and the escapement are held by two hand-engraved cocks. The balance wheel with the hairspring is mounted on the large cantilevered balance cock with a Grossmann micrometer screw, while the escape wheel sits on the smaller, adjacent one. A third, snailed cock holds the lever. Its compact size is deliberate and prevents the view of the escapement from being obstructed.

The index adjuster

The Benu features an index adjuster that allows the watch to be regulated very precisely without disturbing the equilibrium of the oscillation system. The Grossmann micrometer screw enables accurate, tension-free adjustments of the index tail in both directions. In the interest of precise timesetting, the seconds hand stops when the crown is pulled. The stop-seconds device relies on a firm spring that advances a pin onto the circumference of the double roller and temporarily halts the oscillation system.

The stopwork

A modified Glashütte stopwork secures the tension of the mainspring. After winding, it allows the ratchet wheel to reverse somewhat and slightly relax the mainspring. Grossmann’s watchmakers implement this controlled backlash with a slotted hole in which the pin on the stop click can slide.

The three-band snailing

The winding wheels have polished bevel faces in the toothing and sparkle with exceptional brilliance. The largest one, the ratchet wheel, is also decorated with traditional three-band snailing, accentuating a harmonious match with the wide ribbing and the freehand engravings.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

The engravings by hand

All engravings and inscriptons on the 2/3 plate and the balance cock are always engraved by hand.

Tech Specs

Movement

manufacture calibre 100.0, manually wound, adjusted in 5 positions

Special features

Plate movement with 2/3 plate and frame pillars made of untreated German silver, 2/3 plate as well as balance and escape-wheel cocks manually engraved, broad horizontal Glashütte ribbing, three-band snailing on the ratchet wheel, screwed, raised gold chatons, separately removable clutch winder, modified Glashütte stopwork with controlled backlash, adjustment with Grossmann micrometer screw on cantilevered balance cock, handsetting with stop seconds

Functions

Hours and minutes, subsidiary seconds with stop seconds

No. of parts

188

No. of jewels

17 jewels, of which 3 are in screwed gold chatons

Escapement

Lever escapement

Oscillation system

shock-resistant screw balance with Breguet overcoil shaped after G. Gerstenberger

Balance

Diameter 14.2 mm, frequency 18,000 semi-oscillations per hour

Power reserve

42 hours when fully wound

Operating elements

crown 750/000 gold, for winding the watch and setting the time

Movement dimensions

Diameter: 36.4 mm, height: 5.0 mm