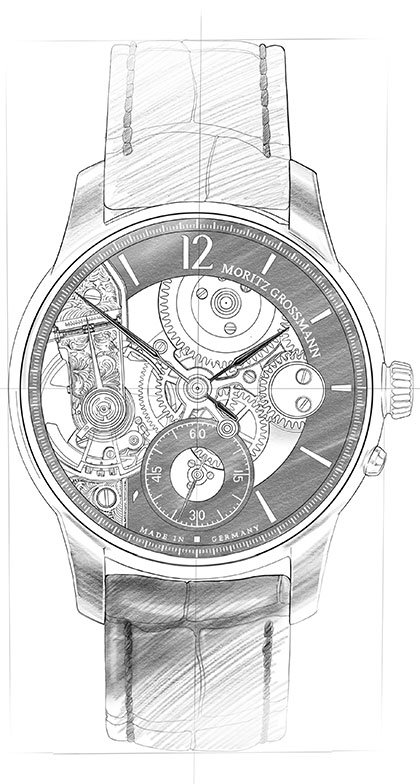

For the calibre 107.0, the rear side of the calibre 100.1 was mirrored and displaced to the front side. In combination with a significantly reduced dial, the artistic special features of the calibre can be prominently showcased. The Grossmann balance, the hand-engraved balance cock, the polished crown wheel, the ratchet wheel decorated with three-band snailing, the minute-wheel bridge, and the lavishly finished handsetting train are easily visible.

In the mirrored movement, a reversal of direction in the mainspring barrel and the going train is necessary for correctly displaying the time. Most of the components were newly developed for this purpose. On the dial side, the pillar movement features the 2/3 plate that is typical for Glashütte timepieces; a massive train bridge graces the other side. In this calibre, swapping the front and rear sides made it possible for the first time to prominently position the manual winding and handsetting mechanism.

Mirrored movement

With a few design tricks, the calibre 107.0 was implemented as a mirror image of the calibre 100.1 movement. To achieve the desired presence of the winding wheels on the dial side, the dial train was reconfigured. The artistically finished train wheels were arranged beneath a lavishly polished minute-wheel bridge. Since in this case, the handsetting mechanism is located on the opposite side of the movement, the setting wheel extends all the way through the calibre. The new arrangement created space for the optimised barrel bearing and the ratchet wheel, which was also shifted to the front side.

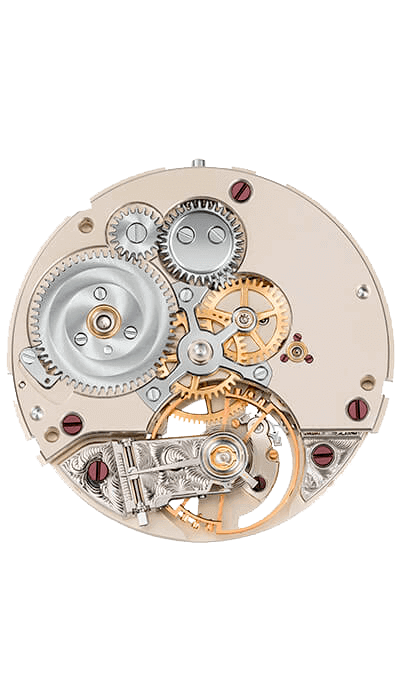

The winder with pusher and stop seconds

On the new rear side of the movement, the winding and handsetting mechanism is now openly integrated in the train bridge, so its functionality can be fully observed for the first time. Nearly all of its parts are mirrored, so their function is readily observable even in the swapped position but with the pusher in the same place. The stop-seconds and stop-balance functions have been redesigned as well. In the handsetting mechanism, the brake position is sampled at the clutch lever and, via a push rod, transferred to the brake spring which then stops the balance. After the pusher is actuated and the movement starts, the brake spring also returns the push rod to its rest position.

The golden chatons

The white sapphire bearing jewels are set in prominent gold chatons. Together with their annealed pan-head screws, they stand out over the datum level of the plate. This raised arrangement, inspired by historic Grossmann pocket watches, makes it possible to remove and clean the bearing jewels individually without risking damage to the plate when resetting them.

Tech Specs

Movement

Manufacture calibre 107.0, manually wound, adjusted in five positions.

Special features

Shock-resistant balance with inertia and poising screws, impulse pin integrated in rim; flat balance spring; balance staff with integrated safety roller; index adjuster with Grossmann micrometer screw; plate movement with 2/3 plate on dial side, frame pillars and separately removable clutch winding mechanism; visible handsetting train on the back side of the movement; frame parts in untreated German silver; Grossmann winder with pusher and stop seconds; raised gold chatons with pan-head screws; remodified Glashütte stopwork with backlash; mainspring barrel with bilateral jewel bearings for optimised power management in the low-torque range; ARCAP train wheels; proprietary escapement with 18-tooth escape wheel; balance cock and crown wheel, intermediate winding wheel and ratchet wheel with stopwork on the modified spring barrel bearing with a gold chaton in the ratchet wheel; dial train wheels spoked and beveled, beneath polished bridge

Functions

Hours, minutes, and subsidiary seconds with stop seconds, Grossmann winder with pusher.

No. of parts

230

Escapement

Lever escapement

Oscillation system

Shock-resistant Grossmann balance with 4 inertia and 2 poising screws, Nivarox 1 balance spring with No. 80 Breguet terminal curve, Gerstenberger geometry.

Balance

Diameter 14.2 mm, frequency: 18,000 semi-oscillations/hour.

Power reserve

42 hours when fully wound

Movement dimensions

Diameter: 36.4 mm, height 5.0 mm