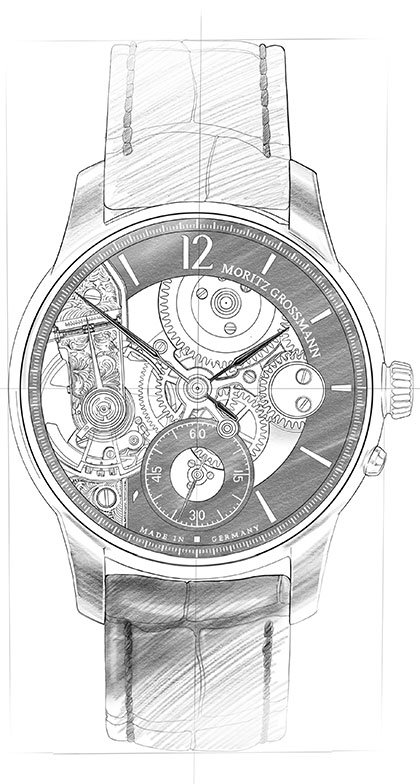

The calibre 106.0 was especially designed for the HAMATIC. This classic pillar movement has a Grossmann plate with six Glashütte stripes. Through the interplay of the hammer body together with head and spring, the automatic hammer mechanism works in both directions. A sapphire roller transfers the oscillation between hammer spring and hammer body.

Two basic scenarios need to be covered by this system in a reliable and energy-efficient manner – very fast movements and the more gentle deflection. The former generate excessive deflections, which need to be attenuated and limited by fixed end stops. This is ensured by intricately crafted end springs in the hammer frame. If the movements are gentler with low hammer amplitude, energy transmission is nearly loss-free.

The hamatic mechanism

The bidirectionally acting automatic hammer mechanism relies on the interaction of the hammer body with the hammer head and the hammer spring. The oscillation of the hammer spring is transferred to the hammer body via a sapphire roller. Hallmarks of the system are efficiency and dependability. In the event of a gentle motion and low amplitude of the hammer, energy transmission is nearly loss-free. Should fast movements and high acceleration rates occur, excessive deflections are attenuated by a catch bracket and limited by fixed end stops.

The reduction gear

In order to convert the energy into a continuous rotary motion, the oscillations of the hammer body are picked up by two click levers. The two-way direction of rotation of the click wheels ensures an even rotary motion, which is transferred to the free wheel via the reduction wheel and then to the ratchet wheel in the mainspring barrel.

The yoke winder

The automatic winding system is complemented by a manual winder designed as a yoke winder that is mounted on a separate bridge. The yoke ensures that the manual winder is always uncoupled from the ratchet wheel when the HAMATIC system is active in response to motion. In manual winding mode, the reduction gear is isolated from the ratchet wheel by a click-pawl idler.

Tech Specs

Movement

Manufacture calibre 106.0, manually wound, adjusted in five positions

Special features

Grossmann balance; click pawl in reduction gear; adjustment with Grossmann micrometer screw on cantilevered balance cock; pillar movement with 2/3 plate and pillars made of untreated German silver, hand-engraved 2/3 plate and cantilevered balance cock; wide, horizontal Glashütte ribbing, double-band snailing on the mainspring barrel; raised gold chatons with pan-head screws; separately removable clutch winding mechanism; stop seconds for hand setting; automatic winding with oscillating hammer, bidirectional click wheels; idler with pawl clicks, manual yoke winder

Functions

Hour and minute, small second with stop seconds

No. of parts

312

No. of jewels

38, of which 3 in screwed gold chatons

Escapement

Lever escapement

Oscillation system

Shock-resistant Grossmann balance with 4 inertia and 2 poising screws, Nivarox 1 balance spring with No. 80 Breguet terminal curve, Gerstenberger geometry

Balance

Diameter 10.0 mm, frequency 21,600 semi-oscillations/hour

Power reserve

72 hours when fully wound

Movement dimensions

Diameter: 36.4 mm, height: 5.15 mm